The reliability and stability of our product quality and processing technology are at the domestic advanced level. We can produce various special specifications of needle rollers and needle ring products according to customer requirements. Welcome customers to come to us for consultation.

The leather punching needle roller and rubber punching needle roller developed and designed by our company use imported alloy steel wire needles with high strength and good wear resistance, with specifications of 0.06~1.50mm. With advanced punching technology, the processing accuracy reaches the world's similar level, and the needle tip flatness is ≤0.06mm.

The base material of this type of needle roller is aluminum alloy and copper alloy. The product punching range is generally 0.10~2.50mm.

This series of products has been used as the first choice to replace imported needle roller punching equipment accessories by many domestic companies. Our company can also professionally design and customize according to customer needs.

Current specifications: needle tip diameter ¢45~¢180.

We mainly engage in customized production, welcome to send email for consultation!

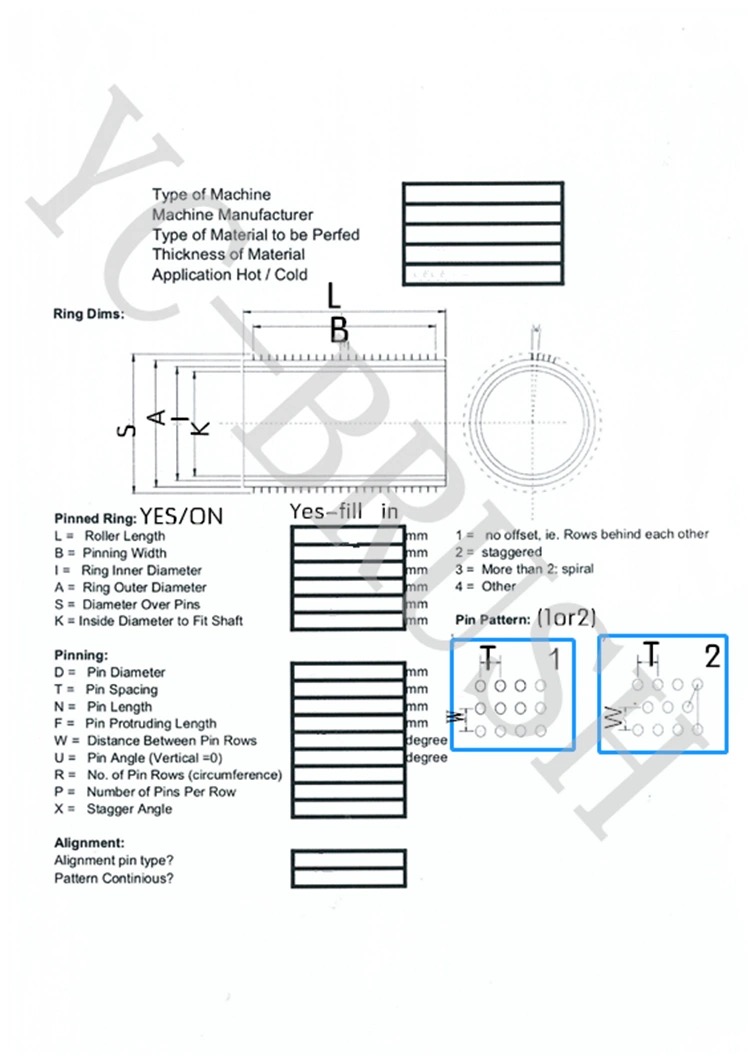

Drum punch roller drawing: