The reliability and stability of our product quality and processing technology are at the domestic advanced level. We can produce various special specifications of needle rollers and needle ring products according to customer requirements. Welcome customers to come to us for consultation.

The hot baby series of perforated needle rollers developed and designed by our company use imported alloy steel wire needles with high strength and good wear resistance. The specifications of the steel needles are 0.6-1.00mm. With advanced punching technology, the processing accuracy reaches the world's similar level, and the flatness of the needle tip is ≤0.03mm. The air permeability detection is uniform and stable.

The needle tip of this series of needle rollers is exposed by 0.50-5mm; the punching gap of the needle roller: the highest density is 1×1mm.

This series of needle rollers is widely used for punching hot baby materials of European temperature difference standards and country A temperature difference standards. There are cold punching needle rollers and heated punching needle rollers for direct punching.

The base material of the cold punching needle roller is copper alloy. The punching range of the product is generally 0.05-1.50mm.

The base material of the heated needle roller is heat-resistant copper, the heating temperature can reach 200°, and the hot hole diameter is between 0.06 and 1.00. Our company can design matching punching fine-tuning devices, temperature control devices, synchronous power systems and punching machines.

Current specifications: needle tip diameter ¢20~¢230

We mainly engage in customized production, welcome to send email for consultation!

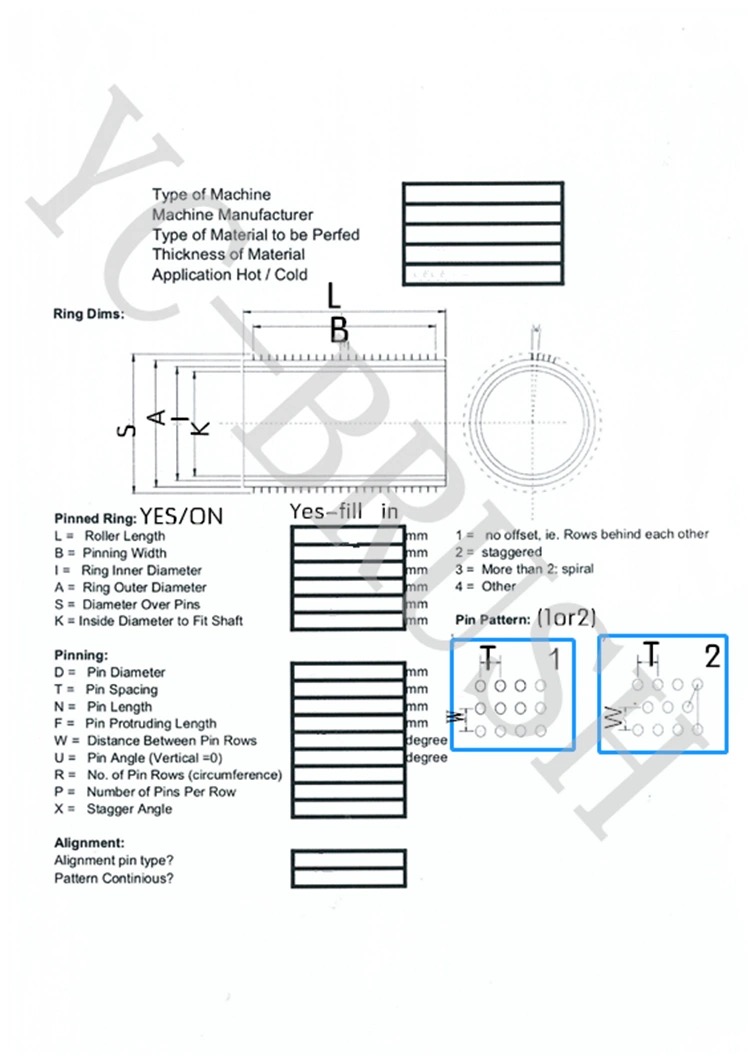

Drum punch roller drawing:

Tags :