Cylinder brushes, also called rotary brushes, can be manufactured with various materials, fibers and densities. Made from a strong, lightweight and balanced steel tubing or polymer tubing, cylinder brushes are commonly mounted and motorized for optimum spin speeds. Multiple core materials and designs are available as well as split core brushes that can be mounted on a shaft without removing the shaft from machinery. Industrial cylinder brushes are commonly used for conveyor cleaning and brushing substrate material on a production line with other common applications, including:

In addition, various industries use cylinder brushes to ensure that there is no contamination, residue or particles remaining on the fabricated parts. Industry settings that you can find cylinder brushes being applied in are sugar and paper mills, smelters and cement, glass and rubber processing, mining plants, plasterboard plants, and food processing plants.

Depending on your application, cylinder brushes can be manufactured using several different core and filament materials. Common cylinder brush filaments include: brass, bronze, nylon, stainless and carbon steel, polyester, natural animal and vegetable fiber.

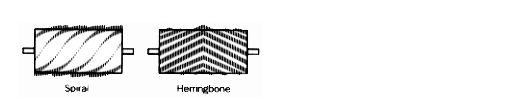

Cylinder & Wheel Brushes are other popular staple-set configurations. Like the blocks, rotary brushes can be manufactured with a variety of core materials, fibers and densities with either a solid or split core. Both can be engineered with STRAIGHT and STAGGERED patterns of tufts. In wider-spaced rows, SPIRAL and HERRINGBONE designs can also be specified.

Cylinder brushes actual length is greater than the diameter, where in wheel brushes the actual brush diameter is greater than the length of the brush.