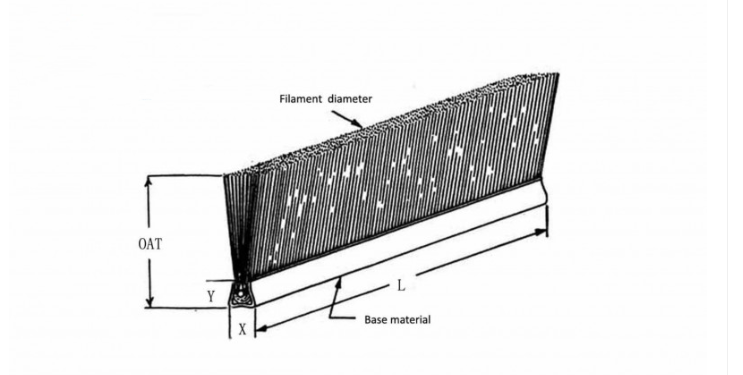

Strip brushes are incredibly versatile in their brush characteristics and shape and can customized to fit almost any application. Because it consists of the brush fillings with a center wire laid down over a continuous flat steel belt formed into a “U” shape channel. Then the fillings pin down by the center wire and inserted into the “U” shape mental channel. As the mental channel is squeeze tightly and closes over the center wire causes the fillings to form vertically into a brush.

Typical applications for straight strips include splash curtains, drag or sweep type conveyor cleaners, tensioning devices, static dissipating, paint booth and conveyor-side seals and product hold-down devices. They are also commonly used in deburring, cleaning, scrubbing, dusting, spreading liquids and powders, polishing, and static dissipation. Strip Brush Design Options Because of the versatility of Strip Brushes in their applications, there is no end to the different combinations between bristle materials with channels. Some of these can include:

Our specialty is providing brush solutions for a broad range of manufacturing problems.Whether it's a custom-designed brush for your special application or OEM replacement, or one of our in-stock designs, we have the experience to handle the most challenging industrial or maintenance applications. See all of our custom strip brush options or give us a call today to talk about your specific strip brush needs.