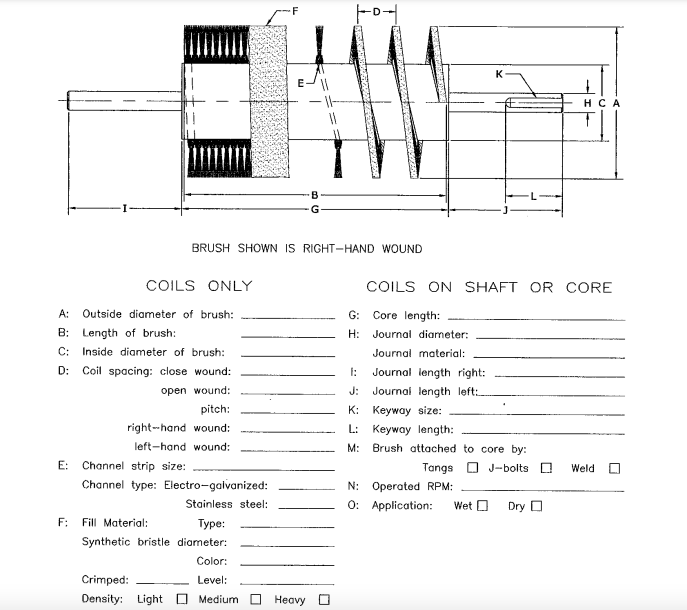

The most common brush with this shape is made with the metal channel on the inside of the brush and the filaments pointing outward. These are called Open Wound Cylinder brushes or Open Coil brushes. They start as regular wound cylinder brushes and are then stretched to the required pitch, sometimes referred to as lead. With this construction, the brush is mounted on a shaft and the filaments work as the brush rotates

Rotary coil brushes, also called cylinder brushes, are industrial cleaning, moving, or sorting brushes made for a variety of applications & industries. The brushes are made to be mounted to equipment, known as "loose coil" or can be adhered to a steel shaft for standalone use.

Industrial coil brushes are made by winding straight metal-backed channel strips on a mandrel, core or shaft to form rotary cylinder brushes. By varying the pitch between each coil, a wide rage of brush densities is possible. From very dense close-wound coil brushes, to progressively less dense more open wound coil brushes, depending on pitch.

This type of brush can be supplied as a complete assembly pre-mounted on a core with journals, wound directly on to a shaft, wound on a customer’s core or shaft, or as replacement coils for in-house installation. Typical applications include conveyor cleaning, panel dusting, glass washing, screen cleaning, material handling (as screws and augers), lint removal and fruit and vegetable washing. Carolina Brush is capable of designing and manufacturing any custom coil brush to meet our customers’ application.